Inspection, Testing & Traceability

Ensuring component quality and traceability

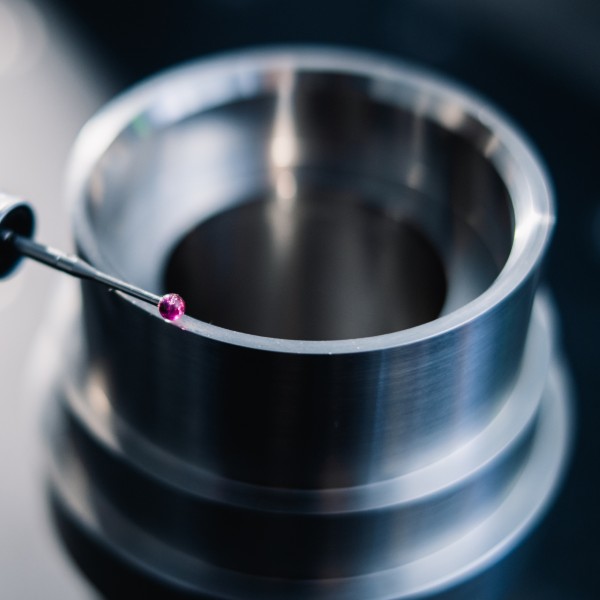

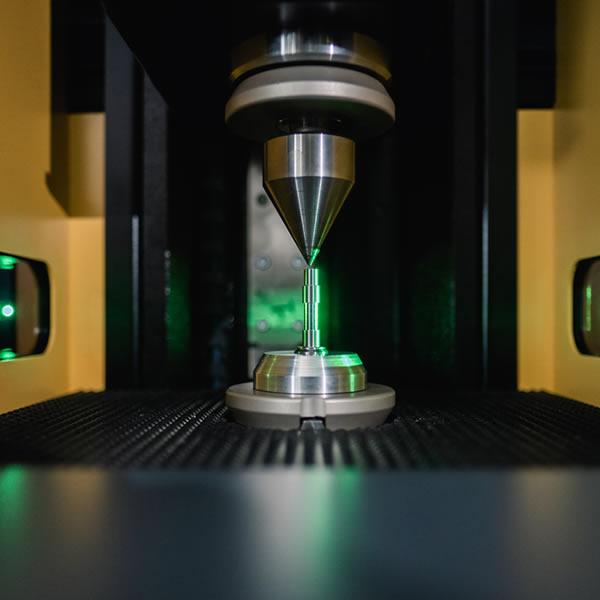

Component testing and inspection plays an important role in ensuring the quality control of manufactured parts. It involves examining individual elements of a product to ensure that they meet the expected standards, both in terms of performance and safety. By subjecting each component to rigorous testing, Cicorel can make sure that our products are safe and reliable for the end-product applications and we help to improve the overall efficiency of a production line by reducing the need for repairs or replacements down the line. In order to get accuracy, we follow a set of well-defined protocols while conducting tests and inspections.

Component traceability

Component traceability is the ability to track and trace the history, usage, and location of components and parts throughout the entire product lifecycle. This helps companies improve product quality, comply with regulations, enhance safety and optimise their supply chain operations.

At Cicorel, we offer full traceability with our manufacturing services so that we can offer our customers:

Quality assurance:

Component traceability allows manufacturers to identify the source of faulty or defective components and address the issue at its root, improving the overall quality of their products.

Compliance:

Traceability is essential for meeting regulations and standards in industries such as aerospace, defence, and medical/healthcare.

Recalls and safety:

In case of a product recall, component traceability enables manufacturers to quickly identify and locate affected components, reducing the risk to consumers and improving the recall process.

Supply chain management:

Component traceability provides visibility into the supply chain, allowing manufacturers to make informed decisions about their suppliers and manage the flow of materials more effectively.

Need enhanced traceability for your component parts?

Every day we deliver quality machining, made to the highest standards.